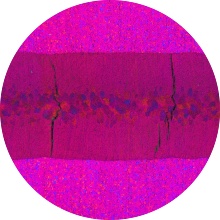

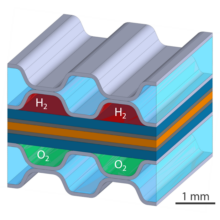

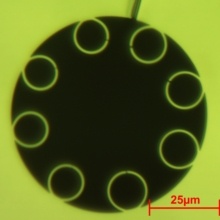

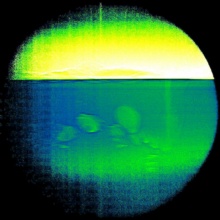

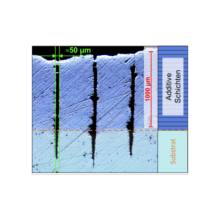

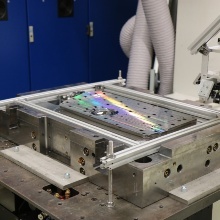

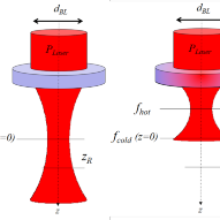

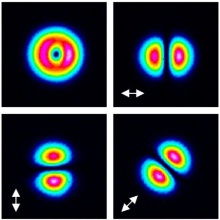

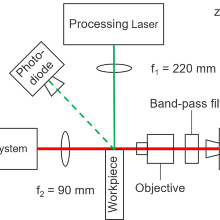

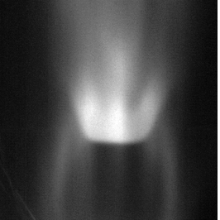

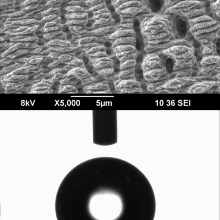

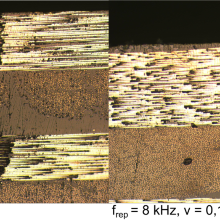

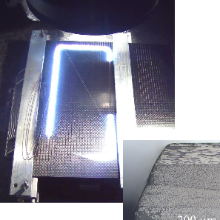

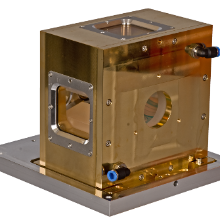

The heat pre-treatment and post-treatment of parts, especially in electron beam processing, are already common working steps today. However, the required heat distribution currently still has to be determined empirically in time-consuming and cost-intensive test series for the respective application. The determination of the required heat flow and the corresponding distribution of the surface temperature is already possible with today's simulation models. At present, however, it is not possible to transfer these temperature fields obtained from the simulation to the workpiece during electron and laser beam processing using a closed-loop control. For this purpose, it is necessary to determine the actual distribution of the absolute temperature on the surface of the workpiece with high precision during the process. This actual temperature distribution is an important element for the control loop and thus a key element for the implementation of temperature-controlled processes.

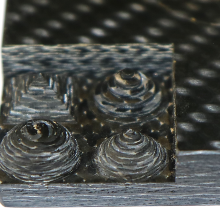

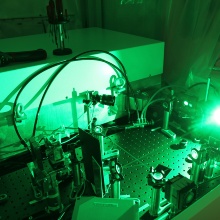

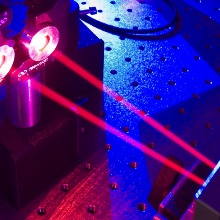

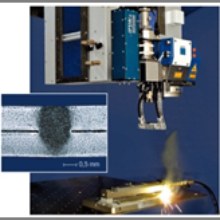

The IFSW addresses this problem together with the Welding and Joining Institute (ISF) of the RWTH Aachen University, as part of the AiF project "Temporally and locally controlled temperature fields in material processing with the electron beam and laser beam" (StrahlClosedLoop). The aim of the project is a temporal and local adjustment and control of temperature cycles in the workpiece during electron beam and laser beam processing according to specifications from a numerical temperature simulation. With this it should be possible to derive heat treatments and surface refinements directly from the material-specific optimum temperature cycles and apply them to the workpieces without test series.

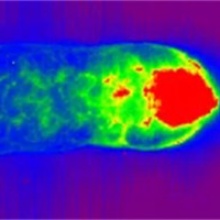

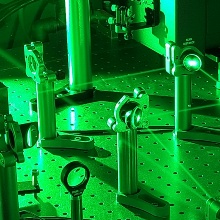

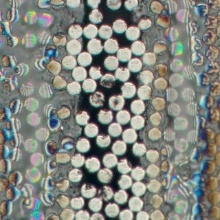

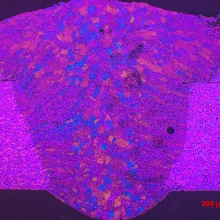

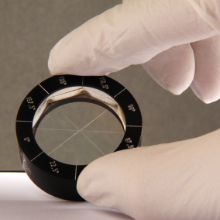

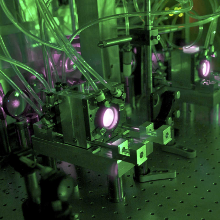

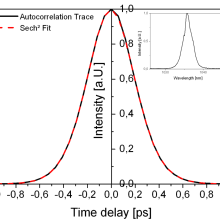

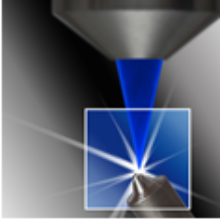

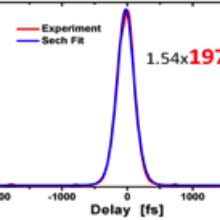

The task of the IFSW within the project is to determine the actual distribution of the absolute temperature on the component surface with high accuracy by means of radiation temperature measurement. The project partner ISF from Aachen is responsible for the conception and development of the control loop.

Contact: Michael Jarwitz