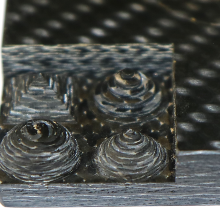

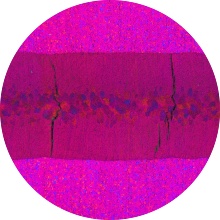

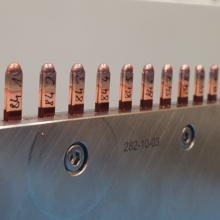

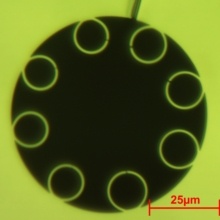

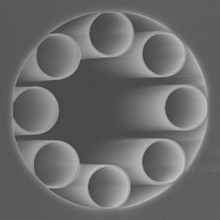

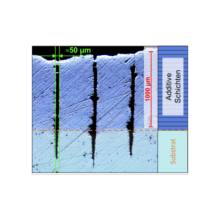

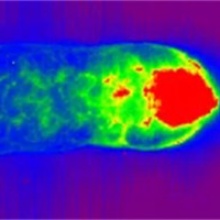

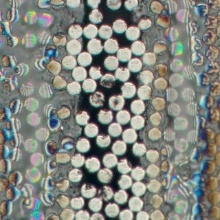

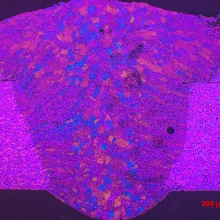

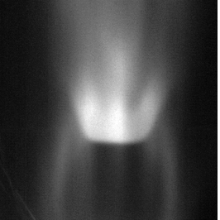

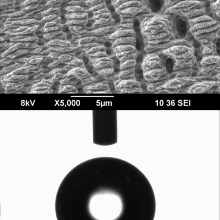

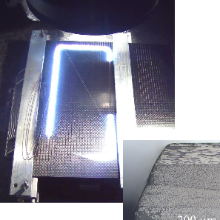

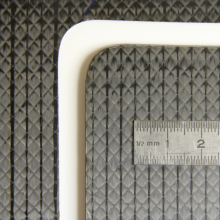

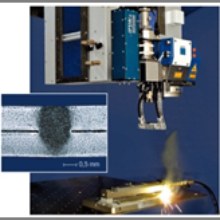

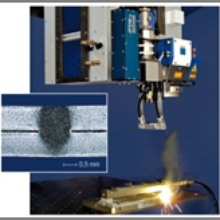

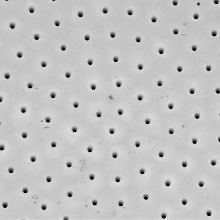

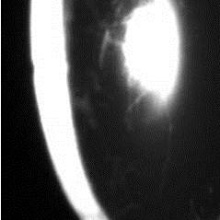

Within the BMBF-project PRECISE, the IFSW created unique structures in carbon-fiber reinforced plastics (CFRP).

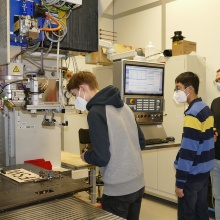

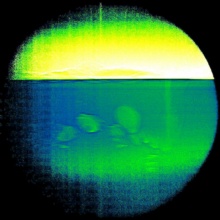

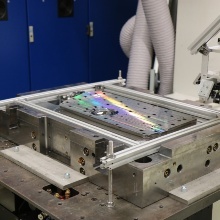

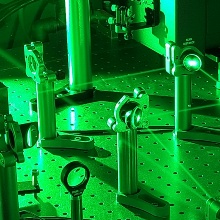

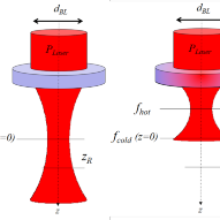

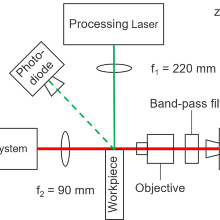

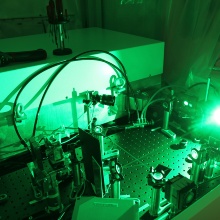

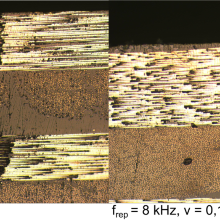

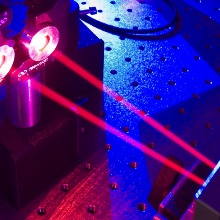

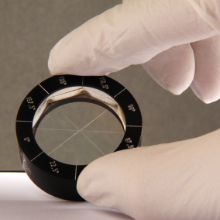

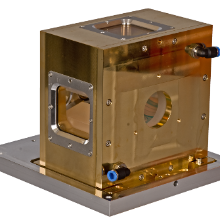

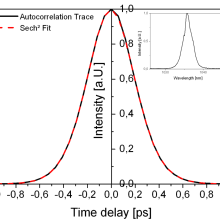

The controlled ablation of complex geometries was enabled by integrating the distance measurement system PRECITEC CHRocodile 2 in one of the laser material processing stations at the IFSW and by developing a control software within the student research project of Matthias Buser. The automated and controlled ablation of predefined geometries is an important step for repairing CFRP parts. The target geometry can be designed e.g. in a CAD program and then be imported into the control software. The controlled ablation process then runs fully automated until the target geometry is reached. A beam source having a wavelength of 1047 nm, a pulse duration of 65 ns, and an average power of up to 21 W was used to produce the demonstration part.

Contact: Daniel Holder (Process Development)