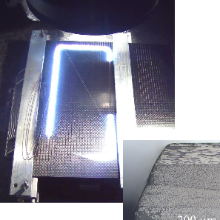

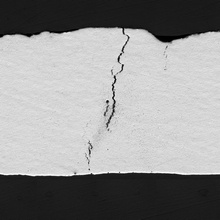

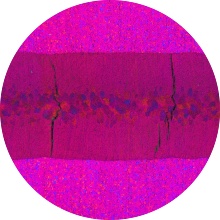

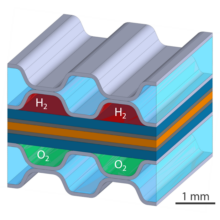

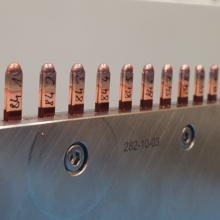

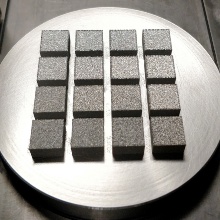

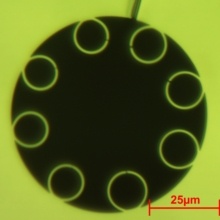

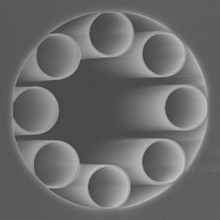

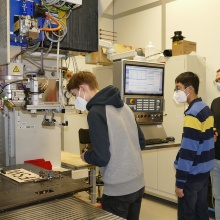

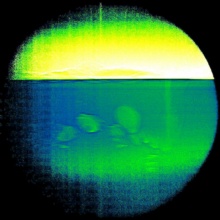

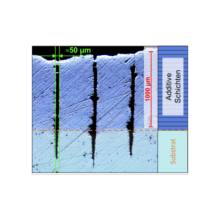

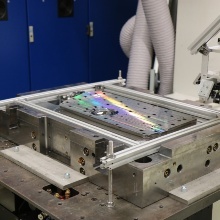

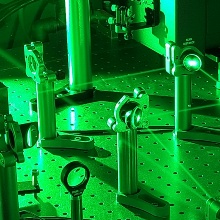

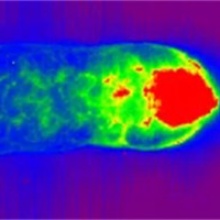

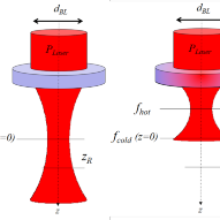

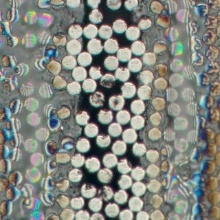

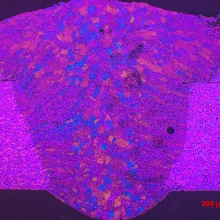

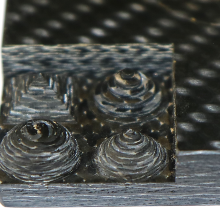

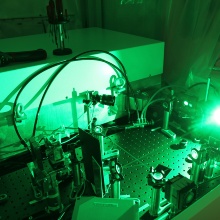

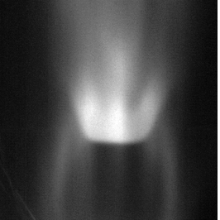

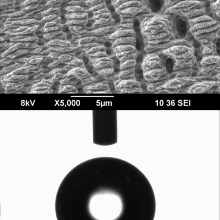

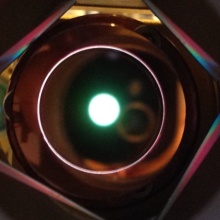

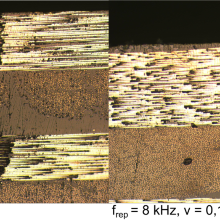

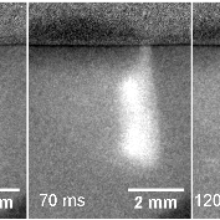

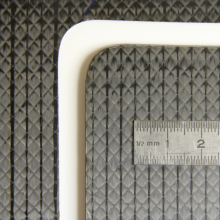

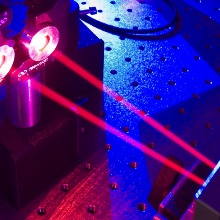

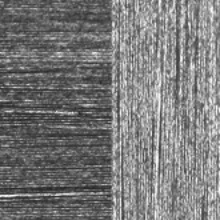

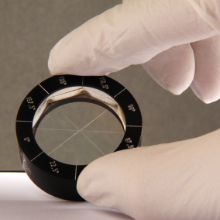

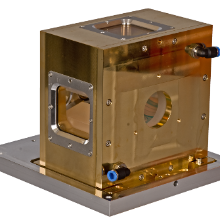

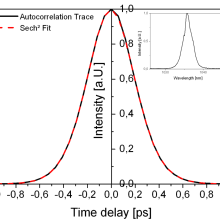

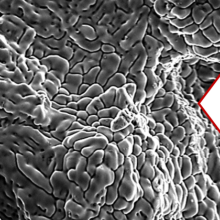

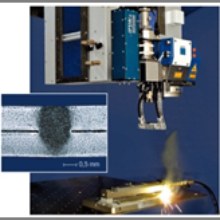

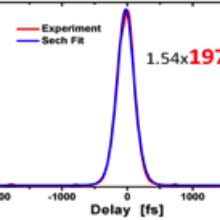

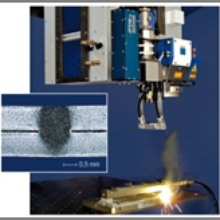

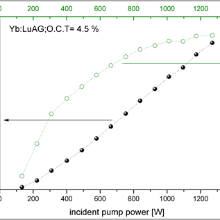

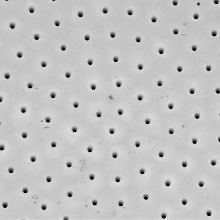

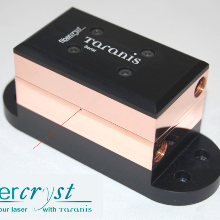

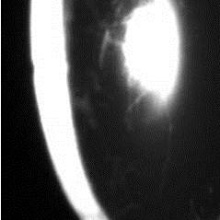

The ultrafast laser recently developed at the Institut für Strahlwerkzeuge (IFSW) which delivers an average laser power exceeding 1.1 kW and pulses shorter than 8 ps enables laser processing of CFRP with minimum thermal damage at high productivity. Profound understanding of the underlying physical processes is however required in this context to minimize quility issues caused by heat accumulation effects. The latest publication related to this topic therefore reports on investigations of the heat accumulation resulting from pulse overlap and from repetitive scans. The impact of these effects can be reduced by a suitable process strategy such as a high feed rate for the scans. A cut through 2 mm thick CFRP samples with a thermal damage smaller than 20 µm was demonstrated at an effective average cutting speed of 0.9 m/min.

For more details see C. Freitag, M. Wiedenmann, J.-P. Negel, A. Loescher, V. Onuseit, R. Weber, M. Abdou-Ahmed, T. Graf „High-quality processing of CFRP with a 1.1-kW picosecond laser“, Applied Physics A (2015) (DOI 10.1007/s00339-015-9159-3).

Contact: Christian Freitag and Dr. Rudolf Weber