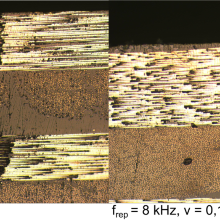

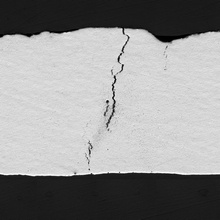

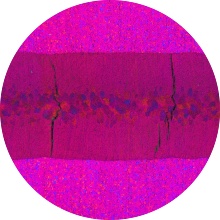

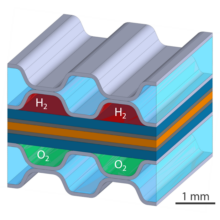

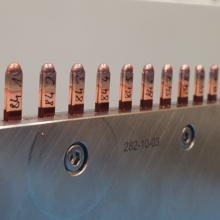

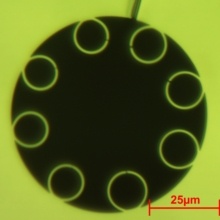

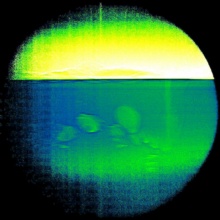

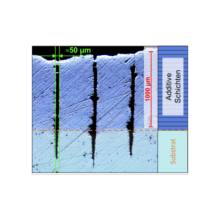

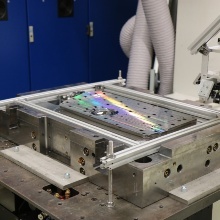

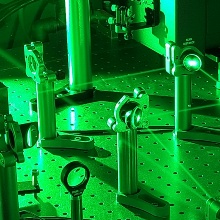

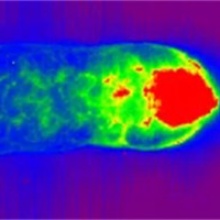

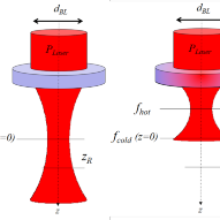

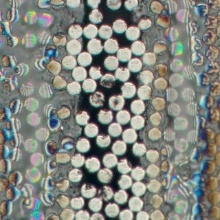

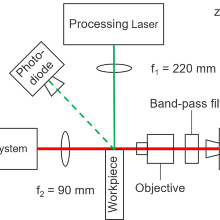

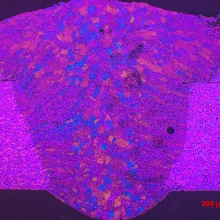

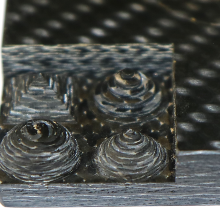

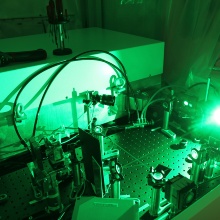

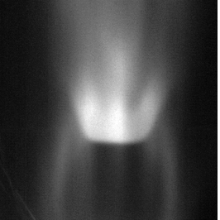

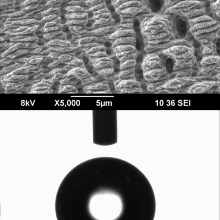

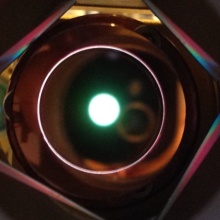

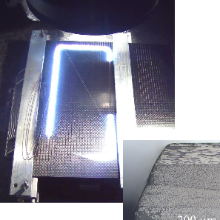

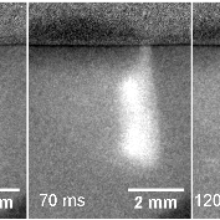

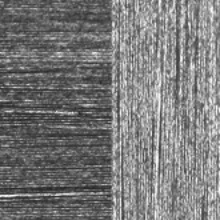

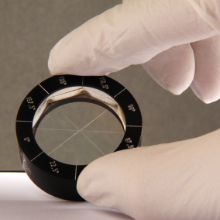

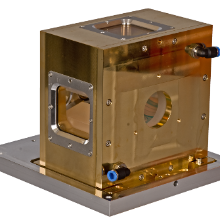

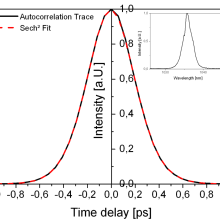

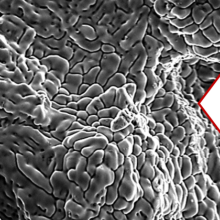

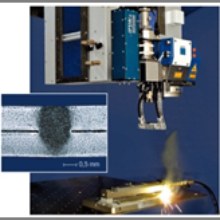

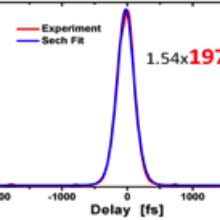

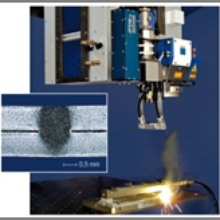

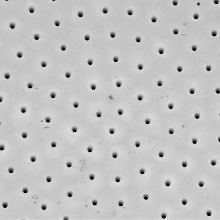

When laser processing CFRP with pulsed laser systems providing high peak intensities, heat accumulation effects are the dominant mechanisms of the formation of thermal damage. The formation of the thermal damage is studied for a wide range of pulse frequencies (ranging from 10 to 800 kHz) and feed rates (ranging from 0.002 to 10 m/s). Three regimes of the formation of thermal damage are found and related with different heat accumulation effects: 1) no heat accumulation with negligible thermal damage, 2) an area of moderate-size thermal damage (up to a few hundred microns) determined by the heat accumulation between pulses, and 3) large thermal damage (up to a few millimeters) caused by heat accumulation between scans. A diagram to illustrate the boundaries between the three regimes of the formation of thermal damage as a function of feed rate and pulse frequency is proposed as a useful tool to optimize the processing parameters and to illustrate the parameter window for damage free CFRP processing.

For more details see T. V. Kononenko, C. Freitag, M. S. Komlenok, V. Onuseit, R. Weber, T. Graf und V. I. Konov, „Heat accumulation effects in short-pulse multi-pass cutting of carbon fiber reinforced plastics”, Journal of Applied Physics 118 (10), 103105 (2015); DOI: http://dx.doi.org/10.1063/1.4930059.

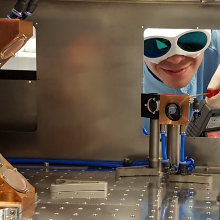

Contact: Christian Freitag and Dr. Rudolf Weber