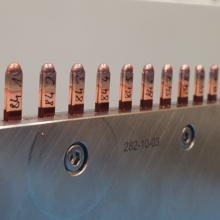

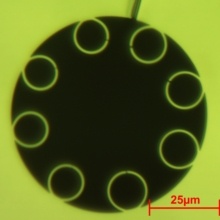

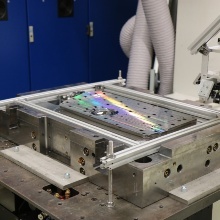

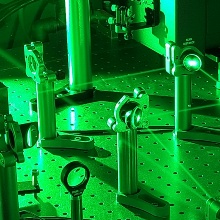

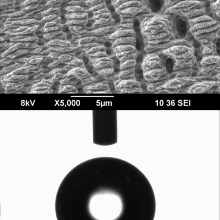

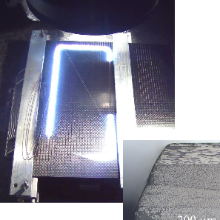

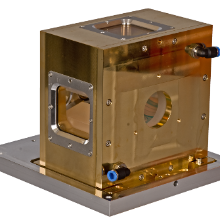

An electrolytic etching and polishing device has been added to the metallography department at the Institut für Strahlwerkzeuge. Electrolytic polishing and etching processes enable a high-quality preparation of samples.

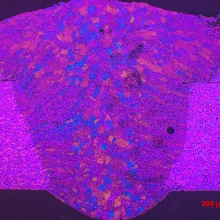

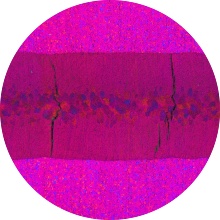

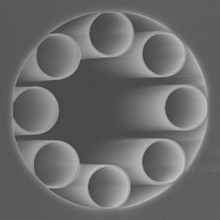

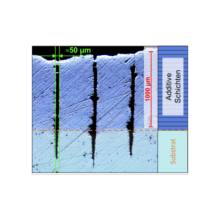

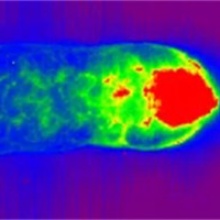

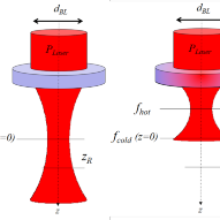

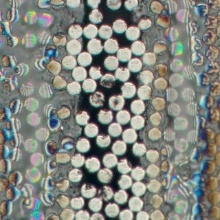

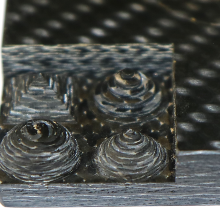

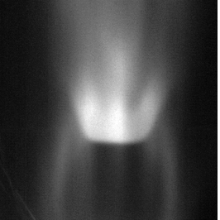

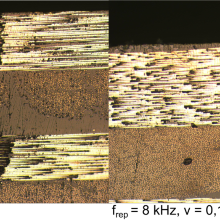

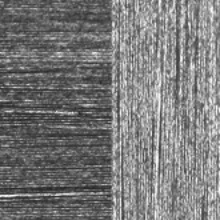

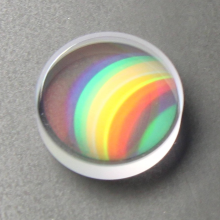

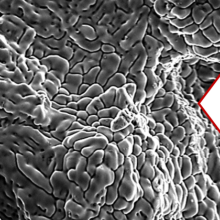

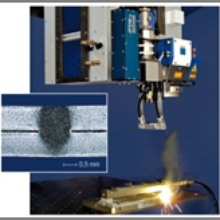

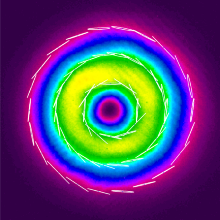

Certain methods also improve the analysis of metallic structures. The electrolytic etching process according to Barker, for example, enables the generation of coloured etching in aluminium alloys. This etching method affects the individual grains of the microstructure depending on their orientation. Observing thus etched samples under linearly polarized light, differently oriented grains are seen in different colors. The individual grains can be better distinguished, identified and measured. The illustration shows the cross section of a weld seam in the AlMgSi alloy AA6016. The oriented dendrites at the sides of the seam and the equiaxed dendrites in the middle of the seam are clearly visible. The growth direction in the observation plane is easy to identify and the size of the grains can be measured.

Contact: Liane Hoster und Christian Hagenlocher