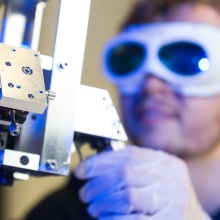

The core research area System Engineering explores the impacts on the system technologies arising from the further development of laser sources and the most recent findings of the process development of laser-based manufacturing processes. System Engineering develops innovative solutions for system technology and laser-based manufacturing facilities starting from the fundamental knowledge on laser-based manufacturing processes. The core research area is focused on solutions for highly dynamic beam delivery, the design of machines and systems, laser safety, and the integration of laser sources, especially in terms of measuring and control technology for established and new laser-based manufacturing processes in order to increase productivity and feasibility of laser processes in an industrial environment.

The system development aims at a high industrial practicability of laser based production processes and is based on the laser technologies and the process fundamentals investigated at the institute. The infrastructure of the process development available at the institute and the newly developed laser sources are used as the development environment.

The aim of the research on System Engineering is to facilitate the feasibility of the developed innovative solutions to increase the productivity and flexibility of laser-based manufacturing processes. The System Engineering follows the approach that the used laser process determines the properties and specifications of the required systems and machines.

Contact

Tobias Menold

Dr.-Ing.Head of system engineering department